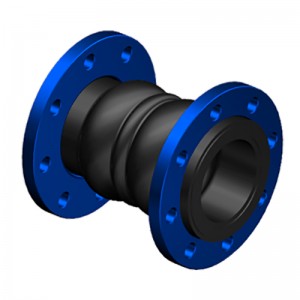

Good quality China Expansion Rubber Joint with Carbon Steel Flange

owing to excellent assistance, a variety of top of the range items, aggressive costs and efficient delivery, we take pleasure in a very good standing amongst our shoppers. We’ve been an energetic corporation with wide market for Good quality China Expansion Rubber Joint with Carbon Steel Flange, We sincerely welcome domestic and international retailers who calls, letters inquiring, or to vegetation to barter, we’ll offer you you good quality merchandise along with the most enthusiastic services,We glance ahead towards your go to plus your cooperation.

owing to excellent assistance, a variety of top of the range items, aggressive costs and efficient delivery, we take pleasure in a very good standing amongst our shoppers. We’ve been an energetic corporation with wide market for China Expansion Joint, Rubber Expansion Joint, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers’ expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, please feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our solutions, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

Details

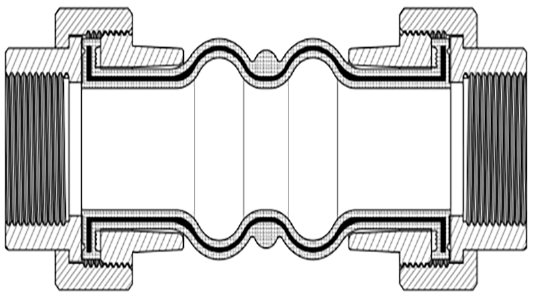

Threaded unions is used When an economical threaded pipe connection is needed, the surface of the union is available both hot-dip galvanizing and electroplating. Both ends provided with a malleable iron union with female thread BS or ANSI.

| Specifications | II | ||

| Working Pressure Mpa (Kgf/Cm2) | 1.6 (16) | ||

| Test Pressure | 2.4Mpa | ||

| Burst Pressure Mpa (Kgf/Cm2) | 4.8 (48) | ||

| Vacuum Kpa (Kgf/Cm2) | 86(660) | ||

| Materials | EPDM/NBR/SBR/NR | ||

| Diameter Range | DN15-DN80 | ||

| Connection Method | THREAD | ||

| Flanges Dimensions | BS, ANSI | ||

| Applicable Medium | Air, compressed air, water, seawater, hot water, oil, acid, alkali etc. | ||

| Loading Port: | Qingdao, China | ||

| Shipment Terms: | FOB, CFR, CIF | ||

| Production Capacity: | 50000 set | ||

| Payment Terms: | L/C, T/T, D/P | ||

| Connection: | THREAD | ||

| Flange Material: | MALLEABLE IRON, DUCTILE IRON | ||

| Period of Delivery | about 21 working days | ||

|

Threaded Union (TU) |

||||||||||||||

|

SIZE |

OAL Length |

Allowable Movement-1 |

Dimensions |

Operating Conditions |

||||||||||

|

Nominal Diameter |

Neutral OAL |

Min Installed |

Max Installed |

Max Compressed |

Max Extended |

Axial Compression |

Axial Extension |

Lateral Deflection |

Angular Deflection |

OAL Fitting |

OAL Body |

Max w.p. (bar) |

Max Vacuum (in. of Hg)-4 |

|

|

Inch |

mm |

|||||||||||||

|

1/2″ |

15 |

8″ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±32.2° |

0.92″ |

6.16″ |

150 |

26″ |

|

3/4″ |

20 |

8“ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±32.2° |

1.00″ |

6.00″ |

150 |

26″ |

|

1″ |

25 |

8” |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±25.3° |

1.25″ |

5.50″ |

150 |

26″ |

|

1-1/4″ |

32 |

8“ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±20.7° |

1.25″ |

5.50″ |

150 |

26″ |

|

1-1/2″ |

40 |

8″ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±17.5° |

1.35″ |

5.30″ |

150 |

26″ |

|

2″ |

50 |

8″ |

7.35″ |

8.12″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±13.3° |

1.60″ |

4.80″ |

150 |

26″ |

|

2-1/2″ |

65 |

9.6″ |

8.95″ |

9.72″ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±10.7° |

2.00″ |

5.60″ |

150 |

26″ |

|

3″ |

80 |

9.6″ |

8.95″ |

9.72′ |

7.13″ |

8.23″ |

0.87″ |

0.23″ |

+/-0.87″ |

±8.9° |

2.00″ |

5.60″ |

150 |

26″ |

|

Threaded Union (TU)-Jis Standard |

||||||||||||

|

Nominal Dia |

Nominal |

Allowable Movements (mm) |

Installation Tolerances (MM) |

OAL Fitting (MM) |

OAL Body (MM) |

|||||||

|

Inch |

mm |

Length (MM) |

Lateral Deflection |

Axial Extension |

Axial Compression |

Angular Deflection |

Lateral Deflection |

Axial Extension |

Axial Compression |

Angular Deflection |

||

|

1/2 |

15 |

180 |

15 |

10 |

15 |

15° |

6 |

3 |

6 |

7.5° |

30 |

120 |

|

3/4 |

20 |

180 |

15 |

10 |

15 |

15° |

6 |

3 |

6 |

7.5° |

30 |

120 |

|

1 |

25 |

180 |

15 |

10 |

15 |

15° |

6 |

3 |

6 |

7.5° |

30 |

120 |

|

1 1/4 |

32 |

245 |

20 |

10 |

20 |

20° |

8 |

3 |

6 |

7.5° |

35 |

175 |

|

1 1/2 |

40 |

245 |

20 |

10 |

20 |

20° |

8 |

3 |

6 |

7.5° |

35 |

175 |

|

2 |

50 |

255 |

20 |

10 |

20 |

20° |

8 |

3 |

6 |

7.5° |

40 |

175 |

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

Jessy Lin

-

WeChat

Ellen Zhang